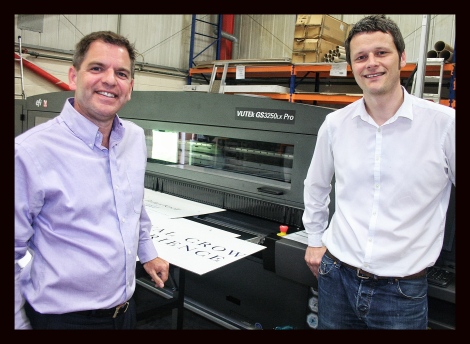

On a grey morning a little over a week ago we took delivery of the single largest capital investment ever made by the company in its 113 year history. Shipped by ocean from the USA within two weeks of order at 7.00am on Tuesday the 11th of June we signed for an EFI VUTEk GS3250lx LED UV Cold Cure 3.2M capacity direct print engine.

This is only the second of these machines delivered into the UK and it will have a dramatic impact on our operation. Weighing in at 3039kg negotiating the machine from the delivery truck and into the production area was no mean feat. The contractors showed almost balletic skill with their fork lift and not inconsiderable daring when examining the lifted devices underside.

This from our recent Press Release

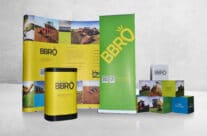

Responding to a steady period of growth in this sector, customer requirement for higher quality and faster turnaround work, and backed by an ethos of embracing green technology and the opening of markets demanding environmental solutions, the VUTEk GS3250LX is the ideal solution.

Replacing the Company’s original NUR TEMPO, the new machine will be sited in our main print production site in Nottingham. This 12,000 square foot industrial unit will service not only their Midlands based branch network but also their nationwide client list.

Working direct with own own end user clients and also being the print provider behind many national agencies and print management companies this significant investment will offer immediate benefits of speed of production, extended range of substrate, increased colour management capability and decreased production costs. John E Wright will be transferring flatbed production to the new VUTEk GS3250LX by the end of June and will be adding new product solutions to our print portfolio over coming months.

Speaking about the decision to make this investment, Managing Director Tony Barnett said “We have always prided ourselves on having the best technology available and this investment provides our customers with another step up in the print quality and speed of turnaround they can expect from us at the very best competitive prices. The new “cool” UV cure technology also means that we can extend our product range into the fast growing fabrics display market, and the significant reduction in power requirement reduces both our costs and our carbon footprint, thereby underpinning our ISO14001 (environmental) and ISO9001 (quality) qualifications of which we are very proud”.

Once the machine was finally in place the technical staff from EFI set about getting it up and running, checking alignments, and installing drivers and RIP software on our servers. The next week or so will be spent on extensive staff training and testing an profiling for print on many of the existing substrates we use but also looking at many of the new fabric media that we will be able to offer.

Print production at the site is managed by Scott Dunn. Whilst it seems he was a little put out that he couldn’t run live jobs on the machine later on during the day of delivery, he and the the rest of the sales and production team are very excited by the huge increases in productivity and range of diverse products they will now be able to offer.

We firmly believe that our customers big ideas need bigger solutions and the EFI VUTEk GS3250lx will enable us to deliver these. Customers with inquires can contact us through the normal channels, using the CONTACT US form on the website or by emailing sales@johnewright.com You can also use the contact form below. To find out more about our capabilities, visit our website using the links on the right hand side of the page.

Error: Contact form not found.